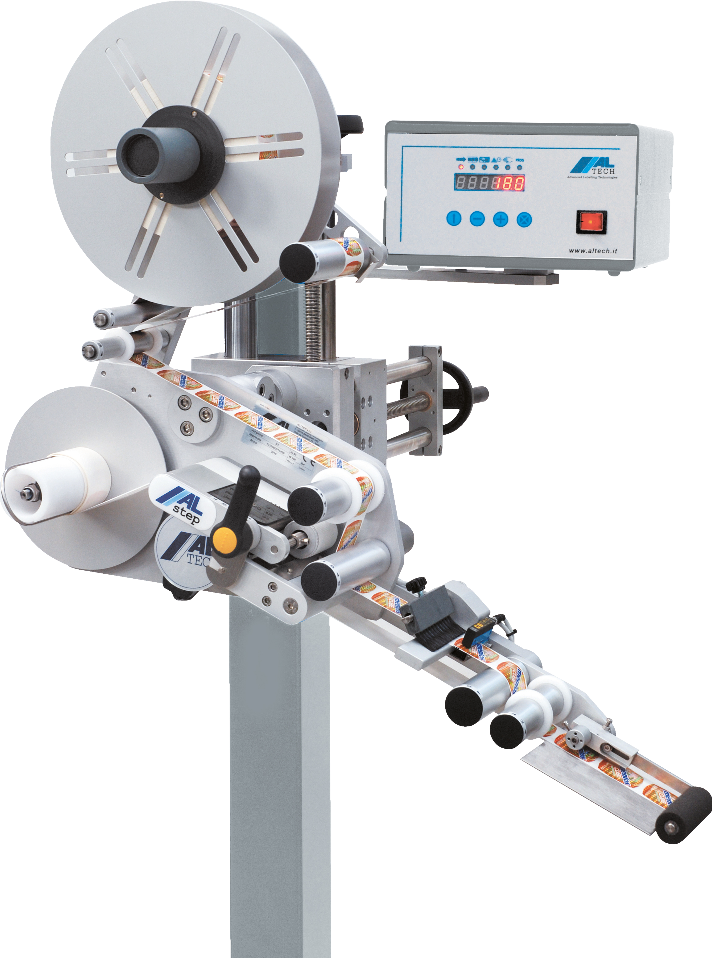

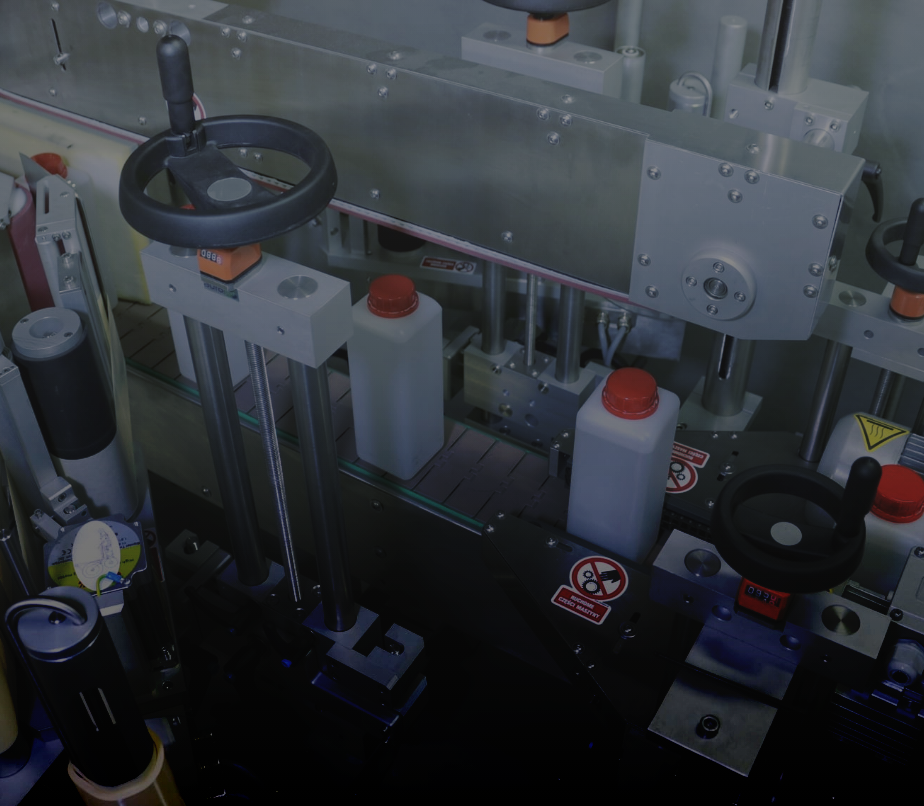

Labelling machines for the most demanding clients.

Labelling machines are a key tool for proper, repeatable product labelling. The devices offered by MGN will optimize production and increase efficiency by several hundred percent. In our offer you will find a wide range of solutions from manual labellers, through automatic labelling machines to advanced printing and labelling systems.

Labelling machines for the most demanding clients.

Labelling machines are a key tool for proper, repeatable product labelling. The devices offered by MGN will optimize production and increase efficiency by several hundred percent. In our offer you will find a wide range of solutions from manual labellers, through automatic labelling machines to advanced printing and labelling systems.

We label each product

Our qualified specialists will help you in choosing the right equipment for the scale of your business. Regardless of the level of difficulty and complexity of the label, we will come to your assistance and help you distinguish your product. Regardless of the location of the label, the type and shape of the packaging, with us you will get the optimal form of presentation of your goods.

Solutions tailored to your needs

In our daily work, we use our many years of experience and know-how in working with clients and effectively advise on creating labels and the way they are applied to the product. If you're looking for the best solution for your business, we're here to help. Not only will we advise you, but we will also select labelling machines tailored to your needs, thanks to which you will stand out on the market. At the end, we will deliver them to your company and support you during the current processes.

Find a solution for yourself

The labelling process should be adapted to your needs and expectations. MGN consultants are qualified specialists, with many years of experience, who will help you in choosing the right equipment for the scale and specificity of your business. We have a wide range of solutions and knowledge, thanks to which we will offer you solutions that meet your needs. We provide you with comprehensive support that will allow you to succeed.

Top

Top

It can be used on any surface - cardboard, jar lid, etc. The application is possible with or without an print. Depending on the needs, we have proven solutions for this.

Bottom

Bottom

The labelling from the bottom requires a special product management, hence our offer includes dedicated solutions together with transporters.

In the case of labellers from the bottom, these are usually constructions based on two conveyors, one behind the other or wedging, so that it is possible to apply a label from the bottom of the product.

Side

Side

The labelling systems on the side of the product are available in both "apply only" and "print and apply" formats.

It is also suitable for affixing barcode identification labels to cardboard boxes and similar large square and rectangular products.

We have experience in the use of labelling on the side, among others, in the furniture industry, and a very demanding labelling for wine bottles.

Front

Front

We have many labelling solutions for applying or printing and applying labels on the front of the product, both presented stationary and in motion.

Typical front labelling solutions include labelling of cartons or automated containers in logistics in the warehouse environment: labelling of products on shrink trays leaving the shrinking furnace and front labelling of the boxes, in line or integrated as part of the carton box sealing machine.

Corner top

Corner top

This is the type of labelling where the label is applied on two sides, from the top and side of the product, potentially sealing the lid or ensuring that the label remains visible when stacked.

It is also a popular solution in the food industry. It performs not only a practical but also a decorative function, e.g. the application of labels to pureed juices, packaging of dietary catering.

Corner side

Corner side

This is the type of labelling where labels are visible on outer cartons, usually to ensure easy identification of the packaging on the pallet.

This solution increases the exposure area of the label and can also serve a decorative function.

We can boast of such solutions, among others, in the automotive industry.

Front and back

Front and back

The front and rear labelling solutions typically consist of two opposite labelling heads, located on both sides of the conveyor transport system, depending on the client's needs at the same time or not.

This solution is particularly useful in the furniture industry and in large warehouses, where it is necessary to mark logistics pallets on both sides.

Around the product

Around the product

This is one of the most advanced types of labelling. The label is applied on four sides of the product, forming a single, coherent whole.

The application around the product is used, for example, for multipacks or abrasive cubes.

Cylindrical

Cylindrical

We have dedicated solutions in the field of labelling machines for products, e.g. candles and diffusers, including candle glasses, boxes and cans, and candlesticks.

When the product is elliptical, oval standard guides are not sufficient to orient it and the machine must incorporate a pre-orientation system and system stabilization, usually in the form of an upper anchorage belt. All these devices must be perfectly synchronized to work properly.

On a bag

On a bag

We have dedicated solutions for labelling both filled and flat bags, including both paper and plastic bags, standing or lying on the conveyor, as well as solutions for feeding and labelling bags offline.

The bag labellers are suitable for both small and large packaging.

D-Wrap

D-Wrap

The D-wrap label is one of the more demanding labelling processes. Our dedicated solutions will meet the most difficult challenges. As in "around the product" labelling, the label is applied to 4 sides of the product, but unlike it, the label does not connect with each other.

Tubes and vials

Tubes and vials

This type of labelling is used to label unstable products. It uses advanced wrapping systems and vial labelling solutions with further capability to apply labels and check printed data.

Excise stamps

Excise stamps

Excise stamp labelling is commonly used on bottles as a separate label or as an integral part of the label on the body.

They are most often used as tax labels or decorative elements.

On 3 sides

On 3 sides

These labelling typically involve pre-dosing the label in front of the deployed, oriented product on the line, and then wrapping the label around the product (using the stabilizer strip).

Documents

Documents

In addition to applying labels, our devices can also be adapted to other tasks. Thanks to the special design of the device, we can print documents such as packing lists, return labels (with backing), invoices or other documents in various sizes to open boxes transported on conveyors.

Palettes

Palettes

We have a wide range of solutions for labelling pallets. From single-axis, medium-pitch, single-side, long-pitch, double-side or multi-side machines, to fully automated and closed multi-sided robotic machines, providing a complete, ready-to-use solution for maintenance-free pallet labelling.

Systems labelling pallets are an indispensable tool for improving warehouse logistics.

Flag type label

Flag type label

This type of labelling allows to apply labels on products with a cylindrical cross-section, e.g. rods, wires, tubes, cables, etc.

The labeller applies a label on the product, and a specially designed adhesive module connects its ends to form a distinctive flag.

You didn't find the right solution?

You didn't find the right solution for yourself? Do not worry! At MGN, we prepare offers tailored to your expectations. Contact us and tell us about your needs – we will be happy to undertake any task, even the most complex.

Types of labelling machines

In our offer we have a wide selection of labellers. From handheld devices to industrial labelling machines that will work well in large companies. Applicators of ready-made labels, labels with real-time printing or labels with printing and buffer. Everything you need. Check out our offer.